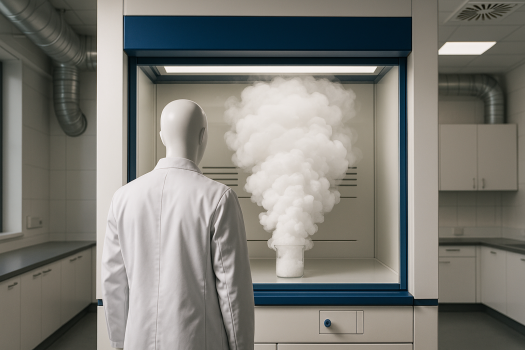

In a laboratory, it’s not just about results – it’s about people’s health, process safety, and the quality of the working environment. A laboratory fume hood is the first line of defense against hazardous vapors, and proper certification under EN 14175 ensures that protection works when it matters most. This article explains why certification matters, how it impacts operating costs and experimental accuracy, and what to consider as early as the lab design stage.

Contents:

- Quality, certification, and internationally recognized standards

- Safety and economic sustainability

- What does EN 14175 specify?

- The fume hood as part of a system

- Impact on experimental results

- Recommendations for selecting a fume hood

- Conclusion

1. Quality, certification, and internationally recognized standards

A laboratory fume hood is not just a piece of furniture – it is a critical safety device that protects personnel and research quality. Across Europe, best practice emphasizes independent fume hood certification rather than relying solely on a manufacturer’s declaration of conformity. The difference is crucial: while a vendor may claim compliance with certain standards, only certification by an accredited testing body provides credible proof of real-world safety and performance.

As with automobiles, promises are not enough – the truth comes from an independent “crash test.” For fume hoods, that role is fulfilled by the test methods in EN 14175, which simulate realistic operating conditions and verify, for example, whether the hood truly contains hazardous vapors within the work chamber.

Products that appear compliant but have not undergone full type testing do appear on the market. Such equipment poses risks to users and research outcomes. By contrast, independent certification confirms that the fume hood has been tested in an accredited laboratory (e.g., an engineering test institute) and certified after successfully meeting all required tests. Even then, ongoing verification is essential: beyond daily visual checks, perform a technical inspection and functional testing at least annually (or more often based on risk) to ensure the hood maintains its declared performance and protective capability.

Decisions about certification requirements, hood specifications, and correct laboratory ventilation connections must be made during the design phase. Later changes are often difficult or impossible, especially for HVAC, spatial layout, and utilities. A high-quality fume hood performs properly only when it is well integrated into the overall laboratory design.

2. Safety and economic sustainability

Investing in a high-quality, certified fume hood pays off through increased laboratory safety and long-term savings. A reliable hood significantly reduces the risk of exposure to toxic vapors, lowers the likelihood of incidents (fires, explosions), and protects staff health.

Modern hoods feature optimized airflow systems – for example, variable air volume (VAV) – that cut energy use and reduce the load on the building’s HVAC. A typical laboratory fume hood can consume energy worth tens to hundreds of thousands in currency annually because conditioned air is exhausted outdoors. With smarter control (e.g., automatically reducing exhaust at closed sash), energy cost savings of up to 50–75 % are achievable.

Certified, well-designed solutions also reduce downtime and operational issues, indirectly saving money. Certification to the relevant parts of EN 14175 assures that the hood is designed and tested to operate safely under real conditions. Combined with properly engineered ventilation, the system proactively prevents issues that could lead to contaminant release or reduced productivity.

3. What Does EN 14175 Specify?

The European standard EN 14175 defines the requirements, construction, and testing methods for laboratory fume hoods. For practical application, these sections are key:

- EN 14175-1: Terminology – defines what can be classified as a fume hood.

- EN 14175-2: Safety and performance requirements – technical criteria to protect personnel.

- EN 14175-3: Type testing – laboratory tests before the product enters the market.

- EN 14175-4: On-site testing – verification after installation.

- EN 14175-6: Fume hoods with variable air volume systems (VAV).

- EN 14175-7: Fume hoods for high-temperature and acid-resistant applications.

Type tests are performed in accredited laboratories. They often involve the use of the tracer gas SF₆, simulating the release of a hazardous chemical, while sensors measure concentrations near the work opening. This verifies the hood’s ability to contain contaminants inside the work chamber under realistic conditions.

4. The Fume Hood as Part of a System

A fume hood is always part of a wider laboratory ventilation system. Its performance and safety depend on proper HVAC design, adequate supply air, and stable pressure conditions. Poorly designed or improperly adjusted ventilation can compromise performance and increase noise levels.

When working with flammable or explosive substances, an ATEX-rated design is essential. There is no universal ATEX fume hood – the exact specification is determined by the External Influences Protocol, which defines the required components and safety features. This must be addressed at the project stage, as later modifications to ventilation or utilities are often difficult or impossible.

5. Impact on Experimental Results

A high-quality fume hood ensures a stable working environment, supporting the repeatability and accuracy of experiments. Poor containment can lead to sample contamination, interference with sensitive measurements, or electromagnetic interference (EMC) affecting laboratory instruments – all of which can compromise research results.

6. Recommendations When Selecting a Fume Hood

- Always require independent certification according to EN 14175 from an accredited testing body.

- Check the supplier’s references and track record in laboratory projects.

- Ensure full technical documentation and ongoing service support.

- Consider operating costs and energy efficiency (e.g., VAV systems).

7. Conclusion

Fume hood certification is not a formality but a critical factor in protecting health, ensuring research quality, and maintaining operational safety. MERCI, s.r.o. provides not only equipment supply but also expert consulting and design support. Safety and quality must always come first – from the planning stage to daily laboratory operation.

Looking for assurance that your laboratory will be safe and fully compliant? Contact us – we will help you choose the right certified fume hood.