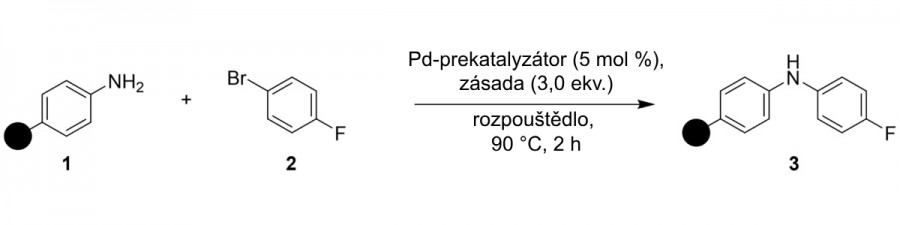

Charnwood Discovery, a research organisation specialising in drug development and process optimisation, needed to efficiently identify the best reaction conditions for a Buchwald–Hartwig amination in the synthesis of a key intermediate (Fig. 1). This reaction is a widely used organic synthesis method that forms a bond between aromatic halides and amines using palladium-based catalysts and appropriate ligands.

Optimising this type of reaction usually requires extensive testing of different catalyst, ligand, base, solvent and temperature combinations. To streamline and speed up the process, Charnwood Discovery used a Design of Experiments (DoE) approach to systematically explore a wide range of parameters and their interactions.

Fig. 1: Buchwald–Hartwig amination scheme.

For this purpose, the advanced Mya 4 reaction station from Radleys was chosen (Fig. 3). MERCI s.r.o. is the exclusive distributor of Radleys products in the Czech and Slovak markets. Mya 4 allows up to four parallel reactions to be run simultaneously with independent control of temperature and stirring. This resulted in a reduction of optimisation time by more than 75% compared to traditional sequential approaches. In addition, sample preparation for analysis was significantly reduced, further improving efficiency.

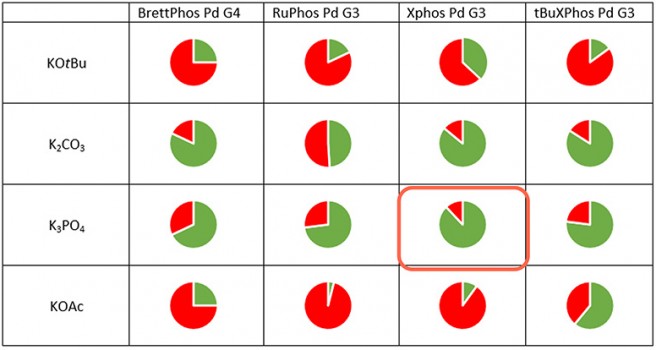

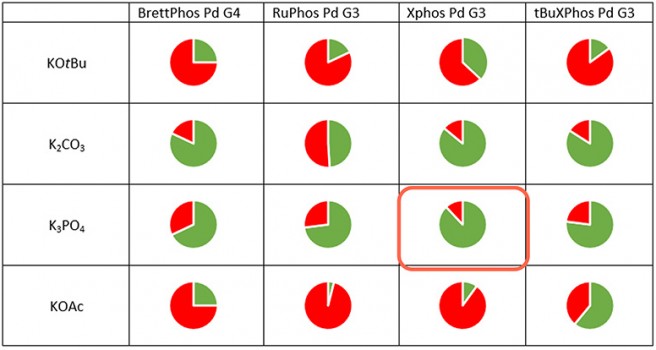

Table 1: Screening results for catalyst and base combinations. Green = high product conversion determined by UPLC-MS. Red = side products and unreacted starting materials.

Catalyst and base screening revealed which combinations led to high yields and which resulted in undesirable by-products or incomplete conversion of starting materials. These results were used to narrow down the parameter space for further optimisation.

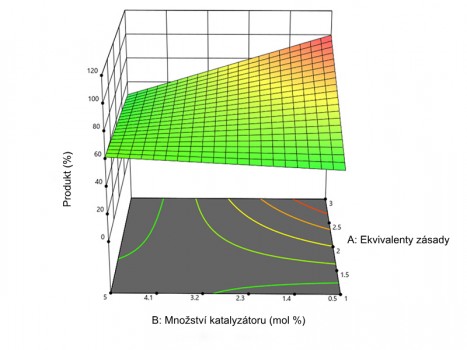

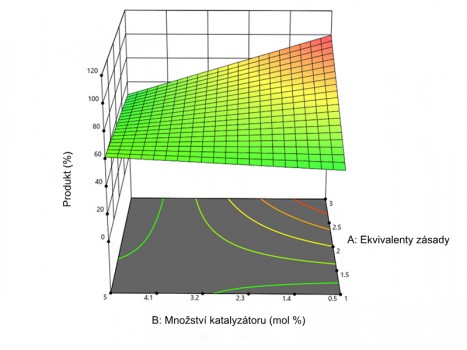

To better understand the interaction between key parameters, such as catalyst loading and base equivalents, a 3D response surface was created (Fig. 2). This visualisation helped researchers to quickly interpret the relationships and efficiently define optimal conditions.

Fig. 2: 3D response graph showing reaction yield as a function of catalyst loading and base equivalents.

By combining Radleys Mya 4 with the DoE methodology, Charnwood Discovery achieved a significant reduction in the time required for chemical reaction optimisation, saved costly catalysts, and reduced development costs in drug discovery. Moreover, the results demonstrated high precision and reproducibility.

Fig. 3: Radleys Mya 4 reaction station for parallel synthesis.

This case study clearly highlights the advantages of modern laboratory technology such as Mya 4, exclusively supplied by MERCI s.r.o., for faster and more efficient drug development and innovation in the chemical and pharmaceutical industries.

Mya 4 is already helping top-tier pharmaceutical companies and CROs in the Czech Republic and Slovakia significantly reduce development and optimisation time. Interested in how it could benefit your team as well? Contact us — we’ll be happy to share practical insights and discuss your specific need

Translated from the original study by Charnwood Discovery in collaboration with Radleys – Jordan, Andrew. (2023): Rapid Optimisation of a Buchwald–Hartwig Amination using DoE.